Due to the fact 1919: the Kaeser results story Find out about our enhancement from the machine store to one of the environment's most prosperous brands of compressed air units.

The calculators within our KAESER toolbox enable you to ascertain the optimisation opportunity of one's compressed air station. KAESER Toolbox

Upcoming the primary products are picked. Some national expectations record acceptable elements with satisfactory temperature ranges and design and style stresses. Style and design stresses are established working with protection components applied to material Homes, which include things like:

Just about every component from the compressor system is essential on the device’s perform. Knowledge these pieces supplies fundamental expertise regarding how rotary compressors perform. Here i will discuss the essential parts:

Titanium: Titanium also offers substantial toughness and rigidity to get a negligible wall thickness. It has superior corrosion resistance and biocompatibility, and It's also non-toxic.

Longitudinal or spiral welds in the leading shell, necks or nozzles, or circumferential welds connecting hemispherical heads to the leading shell, necks or nozzles.

There are no valves on the twin-screw compressor, and there aren't any mechanical forces that make unbalance. This means it may possibly function in a superior shaft pace while keeping a large move fee within a little package deal.

What's more, it has an extended support daily life. Having said that, it can be tough to function and has an increased fabrication Expense. The purity of nickel alloys is essential to protect their energy and trustworthiness.

Firefighting hoses are braided at this very same angle, because usually the nozzle would soar ahead or backward in the event the valve is opened as well as the fibers endeavor to align by themselves alongside the right way.

Oil cooler: The air compression procedure generates an important volume of warmth, which often can cause oil to obtain pretty incredibly hot.

External masses. Hundreds to get viewed as contain wind, snow, and native hundreds for example piping reactions and lifeless pounds of equipment supported with the vessel.

The pressure vessel should not operate at a greater temperature in which the maximum allowable pressure is evaluated. The look temperature website is usually increased than the most working temperature and lesser in comparison to the least temperature.

Corrosion Resistance: This is among The main Qualities of a pressure vessel because it is anticipated for being dependable in severe environments.

This legislation might outline the countrywide normal to which the pressure vessel would be to be built, the involvement of independant inspection for the duration of design, and subsequently the typical inspection and tests through Procedure. Some countrywide pressure vessel requirements such as ASME VIII (1993) or BS5500 (1994) have properly the standing of defacto Global criteria.

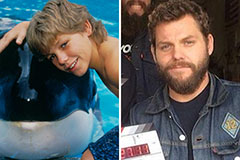

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now!